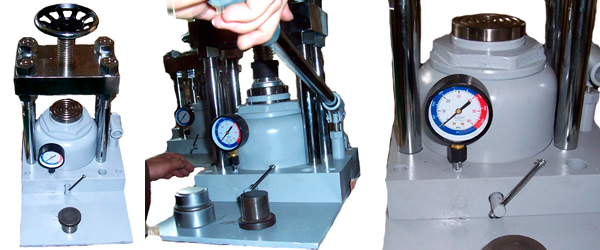

Desktop hydraulic press 40 ton

We are specialized in a variety of models of tablet presses for pressing of tablets with diameter from 3 mm to 100 mm.

A wide range of choice of tablet presses on the website www.Tabletpress.ru

Desktop hydraulic tablet press 40 ton ( Price USD4000,00)

Download the data sheet and user manual for this model of press.

Desktop hydraulic press with pressure of 40 tons. Compact model of laboratory hydraulic press. For pressing tablets with diameter from 10 mm to 100 mm. Press hand, without a motor. Hydraulic press for production of chemical products, briquettes and tablets in powder metallurgy.

Specifications:

Maximal pressure: 400 KN (40 tons kg/cm2)

Maximal tablet diameter: 90 mm

Maximal height of tablets: 60 mm

Diameter of base the upper and the lower punch: 82 mm

The piston stroke: 155 mm

Lever: 490 mm

Overall dimensions: 380mm x 265mm x 390mm

Weight: 55 kg (70 kg with packing)

Desktop hydraulic press for application in chemical and metallurgical industries. Includes spare gaskets and consumables. We produce any molds and dies. The main part of the press is the base plate, base plate combines the carrier racks and the upper base plate. On the base plate mounted hydraulic cylinder, dynamometer and leverage. On the working surface of hydraulic cylinder is installed press tool and die. The screw stopper exercises control of the press cylinder stroke. The entire process operation of the hydraulic press may be divided into:

(a). Filling the matrix,

(b). Compressing of powder,

(c). Ejection of final tablet

These three actions are executed alternately to perform observance of parameters the resulting tablets. Laboratory desktop hydraulic press is a compact, desktop device. After you set the press on the desktop, you can use it. The construction is convenient to assemble or disassemble. Indications 1 MPa = 6,5 KN 1 KN = 0,154 MPa

Installation

Assemble the press, set the matrix on the table surface of hydraulic cylinder, manually fill in the matrix powder, previously have been measured the required weight using measuring cup. Set a punch into the matrix, press down the punch above with screw stop. Set the lever and begin with swinging movements create pressure in hydraulic cylinder. On the dynamometer you will see indications of pressing force that you are creating. Then bleed liquid from hydraulic cylinder, lift up a little level screw. Set the supports underneath the matrix, then again force the effort by lever to press out the finished tablet from the die.

There are no resource except the website www.Tabletpress.ru, which have been collected such detailed info on the production of tablets.

Download the data sheet and user manual for this model of press.

Desktop hydraulic press with pressure of 40 tons. Compact model of laboratory hydraulic press. For pressing tablets with diameter from 10 mm to 100 mm. Press hand, without a motor. Hydraulic press for production of chemical products, briquettes and tablets in powder metallurgy.

Specifications:

Maximal pressure: 400 KN (40 tons kg/cm2)

Maximal tablet diameter: 90 mm

Maximal height of tablets: 60 mm

Diameter of base the upper and the lower punch: 82 mm

The piston stroke: 155 mm

Lever: 490 mm

Overall dimensions: 380mm x 265mm x 390mm

Weight: 55 kg (70 kg with packing)

Desktop hydraulic press for application in chemical and metallurgical industries. Includes spare gaskets and consumables. We produce any molds and dies. The main part of the press is the base plate, base plate combines the carrier racks and the upper base plate. On the base plate mounted hydraulic cylinder, dynamometer and leverage. On the working surface of hydraulic cylinder is installed press tool and die. The screw stopper exercises control of the press cylinder stroke. The entire process operation of the hydraulic press may be divided into:

(a). Filling the matrix,

(b). Compressing of powder,

(c). Ejection of final tablet

These three actions are executed alternately to perform observance of parameters the resulting tablets. Laboratory desktop hydraulic press is a compact, desktop device. After you set the press on the desktop, you can use it. The construction is convenient to assemble or disassemble. Indications 1 MPa = 6,5 KN 1 KN = 0,154 MPa

Installation

Assemble the press, set the matrix on the table surface of hydraulic cylinder, manually fill in the matrix powder, previously have been measured the required weight using measuring cup. Set a punch into the matrix, press down the punch above with screw stop. Set the lever and begin with swinging movements create pressure in hydraulic cylinder. On the dynamometer you will see indications of pressing force that you are creating. Then bleed liquid from hydraulic cylinder, lift up a little level screw. Set the supports underneath the matrix, then again force the effort by lever to press out the finished tablet from the die.

There are no resource except the website www.Tabletpress.ru, which have been collected such detailed info on the production of tablets.

Catalogue of tablet presses

You can explore all models describe the tablet press на www.Tabletpress.ru

- How to choose the tablet press right? There is a wide range of models of tablet presses with different technical characteristics and design features. We'll show you exactly how to choose the press. Only proven practical information.

- The basic errors of presses buyersTabletting is a complicated process requiring preliminary preparation before you make a choice in favor of a certain machine model. Our advices to potential buyers of tablet presses help to avoid mistakes in the selection.

- Discussion about models of tablet pressesComments of expert and technical overview the characteristics of popular models of tabletting equipment. Pluses and minuses. Information is recommended for preview with tablet presses.