Automatic tablet press Model Super press

We are specialized in a variety of models of tablet presses for pressing of tablets with diameter from 3 mm to 100 mm.

A wide range of choice of tablet presses on the website www.Tabletpress.ru

Desktop automatic tablet press model Super press ( Price USD5000,00 )

Download the data sheet and user manual for this model of press.

Desktop single punch automatic eccentric tablet press.

Specifications:

Desktop tablet press Model Super tablet press

Productivity: 3,500 tablets per hour

Maximal pressure: 25 kN (2500 kg/cm2)

Maximal diameter of tablets: from 3 mm to 42 mm

Filling up powder into the matrix: from 2 mm to 20 mm

Power: 1.1 kW | 220V, 1500 rpm

Dimensions: 600mm x 750mm x 500mm

Weight: 110 kg (130 kg with packaging)

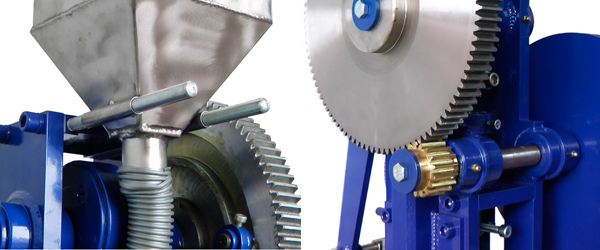

Differences between models Superpress and Reinforced Superpress: the pulley diameter in the model Reinforced Superpress much more, it allows to develop a large inertia (Superpress flywheel weight - 25-30 kg, reinforced Superpress flywheel weight - 40-45 kg). Constructions of gears are also different. In the Reinforced Superpresse is different location of grooves, which have roller lifting and lowering tablet pusher. The depth of filling powder into the matrix of model Superpress is 20 mm, in Reinforced Superpresse - 40 mm, respectively, may be compressed the tablet thicker and larger in diameter (diamter up to 50-60 mm in Reinforced Superpresse, and in Superpresse - up to 45 mm). Constructions of hopper feeders are also different. Hopper feeder has a roller rotating along the contour on the back of large steel gear. In the model Reinforced Superpress this groove is located on the front side. Hopper feeder own allows to adjust the longitudinal course of the hopper. In Superpresse this hopper feeder goes to the depth at rotation the press, and then returned. In Reinfoced Superpresse is the ability to control movement of the hopper: the start and the final stage. It is necessary to qualitative fill with powder the matrix of diameter 50 mm. In Reinfoced Superpresse this function is realized better than in an ordinary Superpresse.

There are no resource except the website www.Tabletpress.ru, which have been collected such detailed info on the production of tablets.

Download the data sheet and user manual for this model of press.

Desktop single punch automatic eccentric tablet press.

Specifications:

Desktop tablet press Model Super tablet press

Productivity: 3,500 tablets per hour

Maximal pressure: 25 kN (2500 kg/cm2)

Maximal diameter of tablets: from 3 mm to 42 mm

Filling up powder into the matrix: from 2 mm to 20 mm

Power: 1.1 kW | 220V, 1500 rpm

Dimensions: 600mm x 750mm x 500mm

Weight: 110 kg (130 kg with packaging)

Differences between models Superpress and Reinforced Superpress: the pulley diameter in the model Reinforced Superpress much more, it allows to develop a large inertia (Superpress flywheel weight - 25-30 kg, reinforced Superpress flywheel weight - 40-45 kg). Constructions of gears are also different. In the Reinforced Superpresse is different location of grooves, which have roller lifting and lowering tablet pusher. The depth of filling powder into the matrix of model Superpress is 20 mm, in Reinforced Superpresse - 40 mm, respectively, may be compressed the tablet thicker and larger in diameter (diamter up to 50-60 mm in Reinforced Superpresse, and in Superpresse - up to 45 mm). Constructions of hopper feeders are also different. Hopper feeder has a roller rotating along the contour on the back of large steel gear. In the model Reinforced Superpress this groove is located on the front side. Hopper feeder own allows to adjust the longitudinal course of the hopper. In Superpresse this hopper feeder goes to the depth at rotation the press, and then returned. In Reinfoced Superpresse is the ability to control movement of the hopper: the start and the final stage. It is necessary to qualitative fill with powder the matrix of diameter 50 mm. In Reinfoced Superpresse this function is realized better than in an ordinary Superpresse.

There are no resource except the website www.Tabletpress.ru, which have been collected such detailed info on the production of tablets.

Catalogue of tablet presses

You can explore all models describe the tablet press на www.Tabletpress.ru

- How to choose the tablet press right? There is a wide range of models of tablet presses with different technical characteristics and design features. We'll show you exactly how to choose the press. Only proven practical information.

- The basic errors of presses buyersTabletting is a complicated process requiring preliminary preparation before you make a choice in favor of a certain machine model. Our advices to potential buyers of tablet presses help to avoid mistakes in the selection.

- Discussion about models of tablet pressesComments of expert and technical overview the characteristics of popular models of tabletting equipment. Pluses and minuses. Information is recommended for preview with tablet presses.