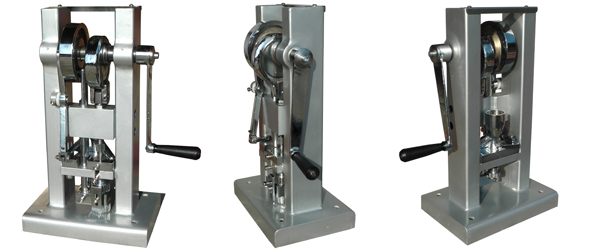

Desktop hand-power tablet press Model 1000

We are specialized in a variety of models of tablet presses for pressing of tablets with diameter from 3 mm to 100 mm.

A wide range of choice of tablet presses on the website www.Tabletpress.ru

Desktop hand-power tablet press Model 1000 ( Price 2500 USD)

Download the data sheet and user manual for this model of press..

We present laboratory desktop hand-power single punch crank-type tablet press. Minimal cost. Compaction force is suitable for tablets from 5 to 9 mm. For more than 10 mm diameter press tonnage is insufficient.

Specifications:

Single punch desktop tablet press model "Tabletpress 1000" Maximal compacting force: 0,7 KN (700 kg / cm 2)

Мaximal diameter of tablets: 10 mm

Minimal diameter of tablets: 4 mm

The thickness of tablets: 5 mm

Productivity: 200 to 800 tablets / hour.

Dimensions: 540 mm x 300 mm x 300 mm

Weight of the tablet press: 20 kg (with packing - 30 kg)

The press is hand, without an electric motor.

New desktop model of hand tablet press - Tabletpress 1000. The model is suitable for private companies, beginners to press tablets, researchers who use the tablet press to produce small batches of tablets, and to laboratories in large industries. The press of small size and easy customization. Tablet press 1000 is an eccentric press. The work of press, transmission is performed by turning the lever on the shaft with an eccentric. Designed for compacting the powder into tablets by 1 piece each. The productivity of the press is 800 tablets per hour. Tablet press 1000 comes with a set of molds: a matrix diameter from 6 to 10 mm and a set of punches. The upper punches are with long body and short shank end, the lower with short body and long shank end. The upper punch set into the upper part of the press. The lower punch serves to eject tablets from the die and is set into the bottom of the tablet press. The press works in manual mode. Before starting work please explore the video with instructions and operating principles. After learning about the rules, operation will be clear and simple. Adjustment and tuning of tablet press is performed in manual mode by turning the lever. Filling up powder into the matrix occurs by the movable hopper feeder. From above the bunker is set funnel for powder. During rotation the lever of press, hopper feeder supplies powder into the matrix, occurs compaction and pushing tablets on the surface of press table.

There are no resource except the website www.Tabletpress.ru, which have been collected such detailed info on the production of tablets.

Download the data sheet and user manual for this model of press..

We present laboratory desktop hand-power single punch crank-type tablet press. Minimal cost. Compaction force is suitable for tablets from 5 to 9 mm. For more than 10 mm diameter press tonnage is insufficient.

Specifications:

Single punch desktop tablet press model "Tabletpress 1000" Maximal compacting force: 0,7 KN (700 kg / cm 2)

Мaximal diameter of tablets: 10 mm

Minimal diameter of tablets: 4 mm

The thickness of tablets: 5 mm

Productivity: 200 to 800 tablets / hour.

Dimensions: 540 mm x 300 mm x 300 mm

Weight of the tablet press: 20 kg (with packing - 30 kg)

The press is hand, without an electric motor.

New desktop model of hand tablet press - Tabletpress 1000. The model is suitable for private companies, beginners to press tablets, researchers who use the tablet press to produce small batches of tablets, and to laboratories in large industries. The press of small size and easy customization. Tablet press 1000 is an eccentric press. The work of press, transmission is performed by turning the lever on the shaft with an eccentric. Designed for compacting the powder into tablets by 1 piece each. The productivity of the press is 800 tablets per hour. Tablet press 1000 comes with a set of molds: a matrix diameter from 6 to 10 mm and a set of punches. The upper punches are with long body and short shank end, the lower with short body and long shank end. The upper punch set into the upper part of the press. The lower punch serves to eject tablets from the die and is set into the bottom of the tablet press. The press works in manual mode. Before starting work please explore the video with instructions and operating principles. After learning about the rules, operation will be clear and simple. Adjustment and tuning of tablet press is performed in manual mode by turning the lever. Filling up powder into the matrix occurs by the movable hopper feeder. From above the bunker is set funnel for powder. During rotation the lever of press, hopper feeder supplies powder into the matrix, occurs compaction and pushing tablets on the surface of press table.

There are no resource except the website www.Tabletpress.ru, which have been collected such detailed info on the production of tablets.

Catalogue of tablet presses

You can explore all models describe the tablet press на www.Tabletpress.ru

- How to choose the tablet press right? There is a wide range of models of tablet presses with different technical characteristics and design features. We'll show you exactly how to choose the press. Only proven practical information.

- The basic errors of presses buyersTabletting is a complicated process requiring preliminary preparation before you make a choice in favor of a certain machine model. Our advices to potential buyers of tablet presses help to avoid mistakes in the selection.

- Discussion about models of tablet pressesComments of expert and technical overview the characteristics of popular models of tabletting equipment. Pluses and minuses. Information is recommended for preview with tablet presses.